Common Mistakes When Using Black Masterbatch in Plastic Production and How to Fix Them

Black masterbatch is one of the most essential additives in the plastic industry, widely used to achieve deep black color, enhance UV resistance, and improve the surface appearance of finished products. Whether applied in injection molding, blow molding, film extrusion, or pipe production, black masterbatch significantly affects the final performance and visual quality of plastic goods. However, improper usage can lead to a variety of defects, increased production costs, and inconsistencies in product quality. Below are the most common mistakes manufacturers encounter when using black masterbatch — and effective methods to solve them.

1. Common Mistakes – Using the Wrong Type of Black Masterbatch

Not all black masterbatch grades are suitable for every application. Some are designed for high-speed film extrusion, while others are optimized for injection molding or high-temperature processes.

Common issues include:

- Low opacity or uneven black color

- Poor dispersion in high-shear processes

- Incompatibility between carrier resin and base polymer

Solution:

Always select black masterbatch based on:

- Correct base polymer (PE, PP, PS, ABS, etc.)

- Processing method (injection, extrusion, blow molding)

- Required loading percentage and final appearance

Working with a supplier that offers tailored formulations ensures better performance and fewer production errors.

2. Common Mistakes – Incorrect Dosing Ratio

One of the most frequent mistakes is using too little or too much black masterbatch. Both can affect product properties and production cost.

Symptoms:

- Using too little: grayish color, translucent areas, low surface gloss

- Using too much: excessive cost, processing instability, poor mechanical properties

Solution:

Follow the supplier’s recommended dosing ratio — typically 2–5% depending on carbon black concentration. Conduct small-batch tests to determine the optimal ratio for your specific equipment and product.

3. Common Mistakes – Poor Dispersion of Carbon Black

Carbon black is a highly concentrated pigment that requires excellent dispersion to achieve uniform color. Poor dispersion leads to streaks, spots, and rough surfaces.

Symptoms:

- Black dots or specks

- “Tiger stripes” on film or molded items

- Rough or matte surface finish

Solution:

- Use high-quality black masterbatch with well-dispersed carbon black

- Increase mixing efficiency or screw speed

- Ensure proper temperature control during plasticization

Choosing masterbatch produced with twin-screw extrusion typically ensures better dispersion and consistent results.

4. Common Mistakes – Overheating During Processing

Black masterbatch contains carbon black, which absorbs heat easily. Excessive heat during processing can degrade the polymer, causing discoloration or burning.

Symptoms:

- Burn marks

- Brittle final products

- Color shift to brownish-black

Solution:

- Reduce barrel temperatures

- Adjust screw speed to avoid excessive shear

- Use black masterbatch with heat-stabilized additives

Proper temperature management prevents polymer degradation and improves product quality.

5. Common Mistakes – Moisture Contamination

Moisture is another common issue when processing black masterbatch, especially in humid environments. Moisture leads to bubbles, voids, and rough surfaces.

Symptoms:

- Bubbles or holes in films or molded products

- Surface imperfections

- Inconsistent color distribution

Solution:

- Store black masterbatch in dry conditions

- Pre-dry the material if necessary

- Use moisture-resistant packaging and proper warehouse management

6. Common Mistakes – Using Low-Quality Carbon Black

The quality of carbon black directly impacts color intensity, UV resistance, and durability. Low-grade carbon black often results in poor performance and inconsistent coloration.

Symptoms:

- Fading or discoloration under sunlight

- Low opacity even at high loading

- Reduced mechanical properties

Solution:

Choose suppliers that use premium carbon black and maintain strict quality control in production. Better raw materials reduce long-term product failures.

Why Choosing the Right Supplier Matters

Many of common mistakes can be prevented simply by selecting a reputable black masterbatch manufacturer that ensures consistent dispersion, high-quality carbon black, and application-specific formulations. A reliable supplier not only improves common mistakes but also reduces downtime, waste, and production costs.

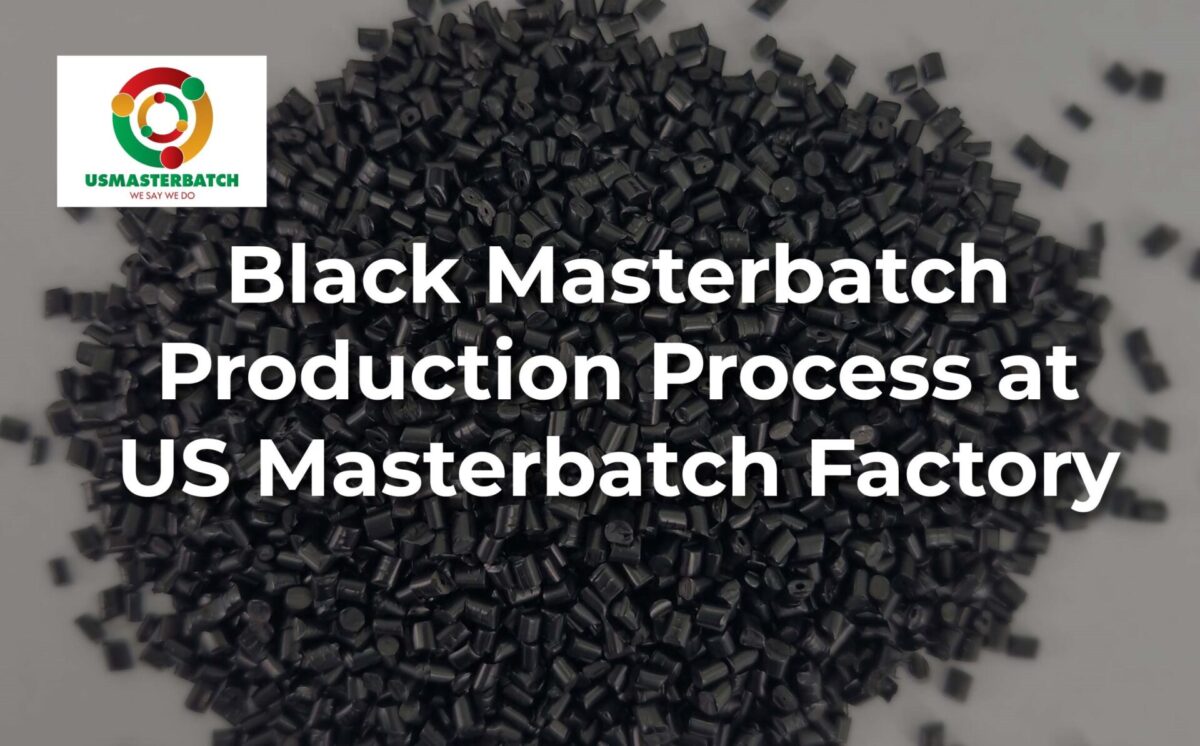

High-Quality Black Masterbatch from US Masterbatch

At US Masterbatch, we offer premium Black Masterbatch designed for injection molding, film extrusion, blow molding, and pipe manufacturing. Our products feature:

- High Jetness and deep black coloration

- Excellent dispersion and smooth surface finish

- UV resistance and heat stability

- Customizable formulations tailored to specific manufacturing needs

Whether you’re looking to reduce defects, enhance product performance, or optimize production cost, US Masterbatch provides reliable black masterbatch solutions trusted by global manufacturers.