Antiblock – The Ultimate Solution for High-Performance Film Production

In the highly competitive world of plastic film manufacturing, operational efficiency and product quality are the twin pillars of success. However, manufacturers frequently encounter a physical phenomenon that can disrupt both: “Blocking”. This is the tendency of plastic films to adhere to one another, making separation nearly impossible without damaging the substrate. To combat this,…

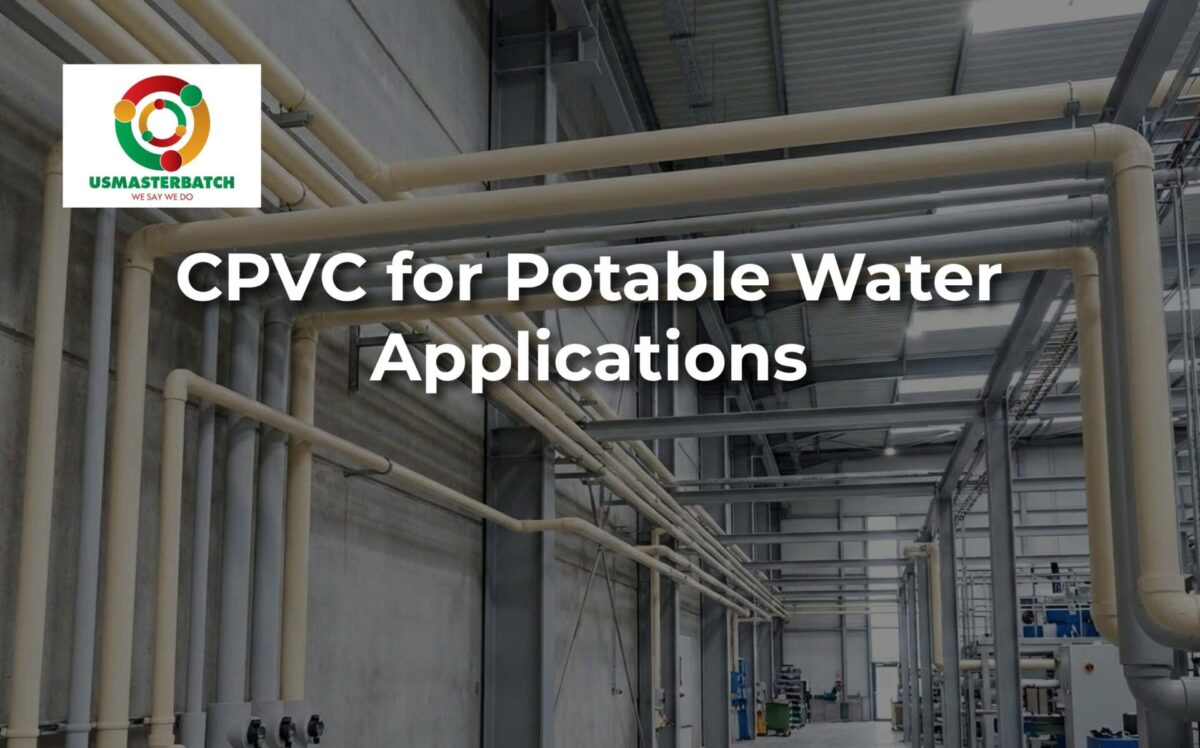

Read MoreCPVC for Potable Water Applications: Safety, Performance, and International Certifications

[US Masterbatch] Clean and safe drinking water is one of the most critical requirements in modern infrastructure. From residential buildings and hospitals to hotels and industrial facilities, piping systems that carry potable water must meet strict standards for safety, durability, and long-term reliability. Among available plastic piping materials, CPVC for Potable Water (Chlorinated Polyvinyl Chloride)…

Read MoreExploring the PVC Compound Manufacturing Process

To manufacture a high-quality plastic product, the input materials play a decisive role. PVC Compound (polyvinyl chloride compound) is the answer to increasingly demanding technical requirements that virgin PVC resin alone cannot fully satisfy. So how are pure white PVC powders transformed into powerful, high-performance compound pellets? Let US Masterbatch walk you through the 6-step…

Read MorePVC Plastic – A Versatile Material with Extensive Applications in Modern Industry

[US Masterbatch] Among widely used polymer materials, Polyvinyl Chloride (PVC Plastic) is recognized as one of the most versatile and reliable plastics in modern industry. Thanks to its adaptability, durability, and cost efficiency, PVC has become an indispensable material across a wide range of sectors, from large-scale infrastructure projects to everyday consumer products. 1. Construction…

Read MoreKey Components of PVC Formulations

Polyvinyl Chloride (PVC) is one of the most unique polymers in the plastics industry. Unlike polyethylene (PE) or polypropylene (PP), which can be processed and used almost directly after polymerization, virgin PVC resin is thermally unstable, difficult to process, and has very limited practical value on its own. That is why every PVC product on…

Read MoreCar Interior Material Types

[US Masterbatch] When choosing a car, most people focus on performance, fuel efficiency, or exterior design. However, car interior material types play an equally important role in comfort, durability, aesthetics, and overall driving experience. From seats and dashboards to door panels and headliners, the materials used inside a vehicle significantly affect its quality and value.…

Read More