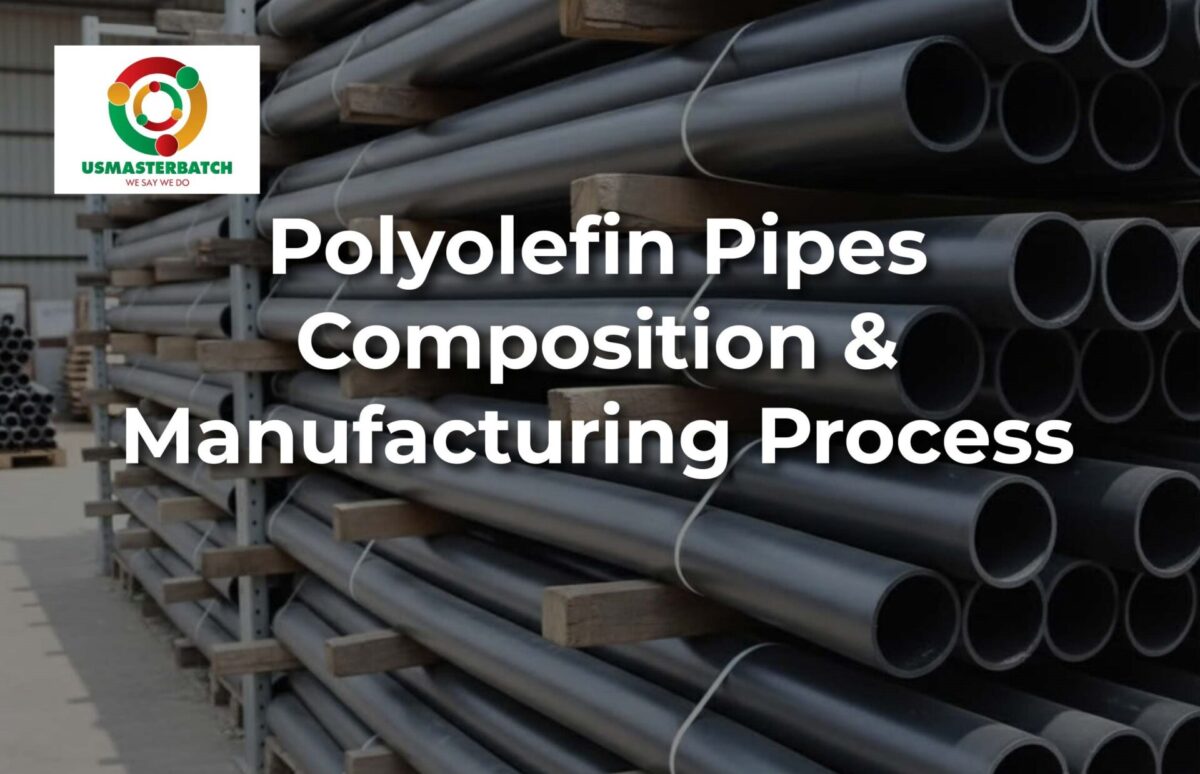

Polyolefin Pipes – Composition and Manufacturing Process

[US Masterbatch] Polyolefin pipes are widely used in modern infrastructure due to their durability, flexibility, and excellent chemical resistance. From water supply systems to gas distribution and industrial applications, polyolefin pipes have become a preferred alternative to traditional metal and PVC pipes. This article explains what polyolefin pipes are, their main components, and the manufacturing process that ensures their high performance and reliability.

1. What Is a Polyolefin Pipe?

Polyolefin pipes are plastic pipes made from polyolefin polymers, mainly polyethylene (PE) and polypropylene (PP). These polymers are thermoplastic materials derived from olefin monomers, such as ethylene and propylene. Thanks to their molecular structure, polyolefin pipes offer a balanced combination of strength, flexibility, and resistance to environmental stress.

Polyolefin pipes are commonly used in:

- Drinking water and wastewater systems

- Natural gas and oil transportation

- Agricultural irrigation

- Industrial fluid handling

Compared to metal pipes, polyolefin pipes are lightweight, corrosion-resistant, and easier to install, which significantly reduces overall project costs.

2. Composition of Polyolefin Pipes

The performance of a polyolefin pipe largely depends on its composition. Although formulations may vary depending on application requirements, the main components are generally similar.

2.1 Base Polymer

The base polymer is the primary raw material and typically accounts for the largest proportion of the pipe composition.

- Polyethylene (PE): Includes HDPE, MDPE, and LDPE. HDPE is the most commonly used for pipes due to its high strength and pressure resistance.

- Polypropylene (PP): Offers higher temperature resistance and stiffness, often used in hot water systems and industrial piping.

The choice of polymer determines key properties such as pressure rating, flexibility, and service life.

2.2 Additives

To enhance performance and durability, various additives are incorporated into polyolefin pipes:

- Antioxidants: Prevent thermal and oxidative degradation during processing and long-term use.

- UV stabilizers: Protect pipes exposed to sunlight from ultraviolet radiation.

- Processing aids: Improve melt flow and surface quality during extrusion.

- Color masterbatch: Provides color coding (e.g., blue for water, yellow for gas) and improves appearance.

These additives ensure that polyolefin pipes meet international standards and maintain stable performance over decades.

2.3 Fillers and Modifiers

In some applications, fillers or impact modifiers may be added to improve stiffness, impact resistance, or cost efficiency. However, high-quality pressure pipes usually limit filler content to maintain mechanical integrity and safety.

3. Manufacturing Process of Polyolefin Pipes

The production of polyolefin pipes is a highly controlled process designed to ensure consistent quality, dimensional accuracy, and mechanical strength.

3.1 Raw Material Preparation

The manufacturing process begins with the selection and preparation of raw materials. Polyolefin resin is mixed with additives and masterbatches according to a specific formulation. Proper mixing is crucial to ensure uniform distribution of additives throughout the pipe.

The blended material is then fed into the extrusion line.

3.2 Extrusion

Extrusion is the core step in polyolefin pipe production.

- The raw material enters a heated extruder where it is melted and homogenized.

- A rotating screw pushes the molten polymer forward under controlled temperature and pressure.

- The melt passes through a die that shapes it into a cylindrical pipe with the desired diameter and wall thickness.

Precise control of temperature, screw speed, and pressure is essential to achieve consistent pipe quality.

3.3 Vacuum Calibration and Cooling

After exiting the die, the hot pipe enters a vacuum calibration tank.

- Vacuum pressure ensures accurate outer diameter and smooth surface finish.

- The pipe is cooled gradually using water spray or immersion tanks to solidify its structure without inducing internal stress.

Proper cooling is critical for maintaining dimensional stability and long-term performance.

3.4 Haul-Off and Cutting

Once cooled, the pipe is pulled forward by a haul-off system at a constant speed. It is then cut into standard lengths or coiled, depending on the pipe size and application.

Automated cutting systems ensure precise length control and clean pipe ends.

3.5 Quality Control and Testing

Before packaging, polyolefin pipes undergo strict quality inspections, including:

- Dimensional checks

- Pressure resistance testing

- Impact strength testing

- Visual surface inspection

These tests ensure compliance with international standards such as ISO, ASTM, and EN.

4. Advantages of Polyolefin Pipe Manufacturing Technology

Modern polyolefin pipe manufacturing offers several advantages:

- High production efficiency

- Consistent product quality

- Low material waste

- Long service life (often exceeding 50 years)

Advanced extrusion technology allows manufacturers to produce pipes with excellent performance while meeting environmental and sustainability requirements.

5. Conclusion

Polyolefin pipes combine advanced polymer materials with precise manufacturing processes to deliver reliable, long-lasting piping solutions. Understanding their composition and production process helps engineers, contractors, and buyers make informed decisions for water, gas, and industrial projects. With continuous innovation in polyolefin materials and extrusion technology, polyolefin pipes will remain a key component of modern infrastructure for years to come.