Common Issues When Using White Masterbatch in Plastic Production and How to Resolve Them

What is white masterbatch?

White masterbatch is a white plastic color concentrate produced by combining Titanium Dioxide (TiO₂) pigment with a polymer carrier resin (such as PE, PP, PS…) along with dispersing additives. It is used to create a white color, increase opacity, and improve the surface quality of plastic products.

Today, our company US Masterbatch will help you gain a clearer understanding of the nature of white masterbatch, how it works, and why it is widely used. In addition, we will analyze the common issues that often occur when using white masterbatch in production and help you identify their causes as well as the signs to recognize these problems.

Main Components

- Titanium Dioxide (TiO₂)

This is the primary whitening ingredient, responsible for increasing whiteness, opacity, and brightness of the final product. Rutile-grade TiO₂ is commonly used due to its strong UV resistance and excellent light-reflecting properties. - Carrier Resin

The carrier can be PE, PP, PS, or ABS depending on the application. It helps disperse TiO₂ uniformly throughout the product and ensures compatibility with the customer’s polymer base. - Additives

These include dispersing agents, anti-agglomeration additives, or gloss enhancers. Their purpose is to improve TiO₂ dispersion, create a smoother surface, and stabilize the material during processing.

What Products Can White Masterbatch Be Used For?

White masterbatch is widely used across the plastics industry thanks to its bright white color, high opacity, and ability to improve product surface quality. Below are the most common application groups:

- Plastic Films

- PE, HDPE, LDPE bags

- Shopping bags, garbage bags

- Food packaging films

- Stretch and shrink films

- Fibers and Woven Packaging

- PP tapes

- Woven PP bags, jumbo bags (FIBC)

- Raffia straps

- Injection Molding

- Household items: containers, basins, baskets

- Technical PP, ABS, PS components

- Plastic housings and parts

- Extrusion

- PE pipes, technical plastic pipes

- PE/PP plastic sheets

- Blow Molding

- HDPE bottles, plastic cans

- Chemical, cosmetic, and food containers

Below, US MASTERBATCH will outline the common issues you may encounter when using white masterbatch.

-

White masterbatch does not disperse completely in the polymer – Common Issues

When the final product shows white specks, streaks, or uneven whiteness, the cause is usually incomplete dispersion of fillers (CaCO₃, TiO₂), carrier resin, or additives within the polymer.

This often occurs when shear force in the extruder is insufficient, temperature settings are incorrect, or the machine is old, causing alternating hot–cold zones. As a result, the masterbatch does not melt properly and forms agglomerates, leading to rough surfaces, streaks, or poor whiteness.

Solutions (technical – processing)

1) Pre-dry the material before use

- Dry at 80–90°C for 2–3 hours for PE/PP.

- Check moisture using a moisture tester; required value: < 0.1%.

- Avoid using masterbatch bags opened for more than 24 hours in high humidity.

2) Improve dispersion during processing

- Increase screw RPM to raise shear force.

- Increase head pressure to ensure better melting and dispersion.

- Check screw wear — if wear is >10%, replace it to avoid loss of shear strength.

3) Adjust machine temperature zones

- Increase temperatures in zones 1–2 to soften the carrier resin more effectively.

- Stabilize mid-zone temperatures to avoid fluctuations of ±5°C (a common cause of agglomeration).

- Raise die-head temperature by 5–10°C to stabilize flow and improve surface finish.

-

Insufficient whiteness, yellowing, or dull appearance – Common Issues

This issue occurs when TiO₂ purity is low, contaminated with metal oxides, or when the carrier resin degrades due to excessive heat. Thermal degradation produces a slight yellow tint, reducing TiO₂ opacity.

Additionally, CaCO₃ with high impurity content or improper particle size can make the product look dull and less bright.

Solutions (technical – processing)

1) Use high-quality TiO₂

- Prefer Rutile TiO₂ grades such as R706 or R902+ for optimal anti-yellowing stability.

- Check brightness levels: L ≥ 98* for ensured whiteness.

- Use masterbatch with TiO₂ content ≥ 50% for high-whiteness applications.

2) Adjust processing temperature to prevent burning

- Lower temperatures in the upper zones of the machine, especially zones 3–4, to avoid polymer burning.

- If smoke or burnt smell appears → immediately reduce temperature by 10–15°C.

- Reduce polymer residence time (lower screw speed during machine pauses).

-

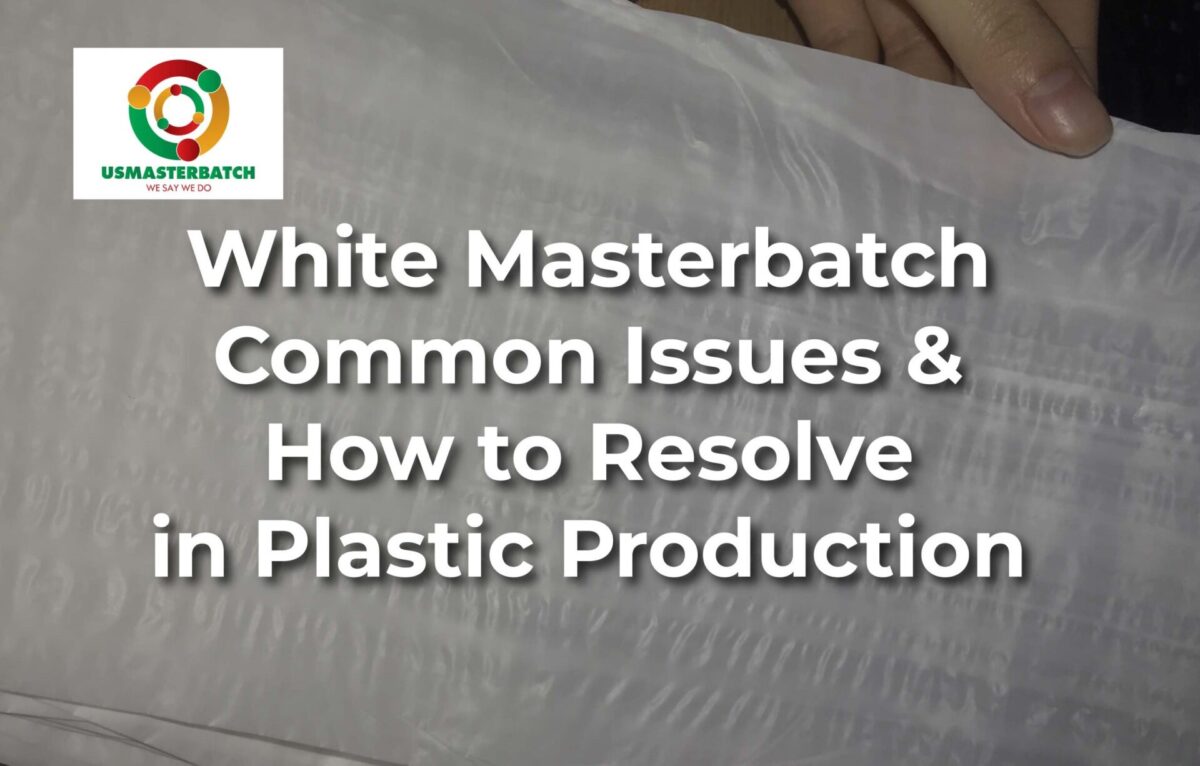

White streaks or bright streak marks on the product surface – Common Issues

This common defect appears when the white masterbatch has a melt index (MI) incompatible with the polymer base, causing poor melt blending and flow marks.

Sudden changes in draw-down speed or product thickness can also stretch the masterbatch unevenly, leading to streaks.

Solutions (technical – processing)

1) Choose masterbatch with a suitable MI

- For PP: use MI 12–20 for good melt blending.

- For PE film: use MI 2–4 to prevent phase separation.

- Check carrier compatibility: PP carrier should not be used for PE, and vice versa.

2) Optimize operating parameters

- Reduce draw-down speed by 5–10% if streaks appear in films or blown packaging.

- Increase back-pressure by 10–20 bar to stabilize melt flow.

- Inspect the melt filter/screens — if clogged, they cause unstable flow.

3) Optimize die design and cooling

- Clean the die head to remove TiO₂ deposits that cause flow imbalance.

- Adjust cooling fan distance to avoid uneven shrinkage.

- For injection molding, increase holding pressure by 5–10% to eliminate weld-line streaks.

So we have reviewed the three most common issues that occur when using white masterbatch and learned how to identify them as well as the proper solutions. These defects can arise at any stage — from blending, processing, to raw material storage conditions. However, with the right knowledge and experience, they can be fully controlled and effectively eliminated.

At US Masterbatch, we are proud to be one of the suppliers delivering stable, consistent, and high-quality white masterbatch that meets a wide range of requirements in the plastics industry. Our products are made from strictly tested raw materials, ensuring high whiteness, excellent dispersion, and optimal compatibility with various polymers. As a result, customers can rely on consistent color durability, smooth surface quality, and high processing performance.

We are fully committed to quality assurance and always stand by our customers throughout the entire production process. Whenever you face a technical issue, formulation concern, or need process consultation, the US Masterbatch technical team is ready to support you quickly and accurately. Our goal is not only to supply products, but to help customers maintain stable production, optimize costs, and achieve the best possible output quality.

📧 Email: info@usmasterbatch.com

🌐 Website: https://usmasterbatch.com/