Which roles does TiO2 play in White Masterbatch?

- What is titanium dioxide an excellent white pigment used in?

Titanium dioxide is a white pigment, the first pigment produced in the world, most widely used for its brightness and very high refractive index in a very broad range of applications including paints, inks, plastics, paper, fibers, ceramics, food and cosmetics, etc

Titanium dioxide has some interesting characteristics: low cost, high thermal, mechanical-chemical stability, and high photo-activity,

It is a polymorph oxide that exists in three different forms: brookite, anatase, and rutile. All three forms can be synthesized at the laboratory in the form of a white powder.

- What is the use of titanium dioxide in plastics?

The titanium dioxide plays an important role in the plastics industry and has broad application prospects

Almost all thermosetting and thermoplastic plastics will use titanium dioxide, such as polyolefins (primarily low-density polyethylene), polystyrene, ABS, polyvinyl chloride, etc. It can be mixed with dry resin powder or liquid containing plasticizers. There are also some plastic manufacturers who process titanium dioxide into masterbatch before use.

Since the coating film of plastic products is much thicker than paint and ink, it does not require too high pigment volume concentration. In addition, titanium dioxide has high hiding power and strong coloring power, and the general dosage is only 3%~5%.

Most of the titanium dioxides for plastics have a relatively fine particle size. Usually, the particle size of titanium dioxide for coatings is 0.2~0.4μm, while the particle size of titanium dioxide for plastics is 0.15~0.3μm so that a blue base phase can be obtained. This has a covering effect on most yellowish resins or resins that are prone to yellowing.

The titanium dioxide for ordinary plastics generally does not undergo surface treatment. Because titanium dioxide coated with inorganic substances such as conventional hydrated alumina is used, when the relative humidity is 60%, the adsorption equilibrium water is about 1%. When the plastic is extruded at high temperature, the evaporation of water will cause pores on the smooth plastic surface

- What is the role of TiO2 in White Masterbatch?

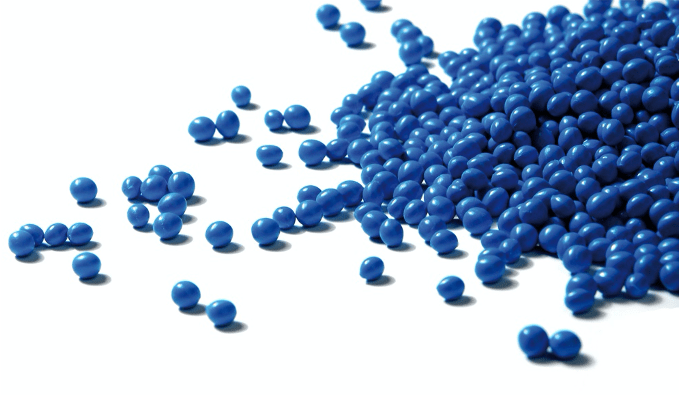

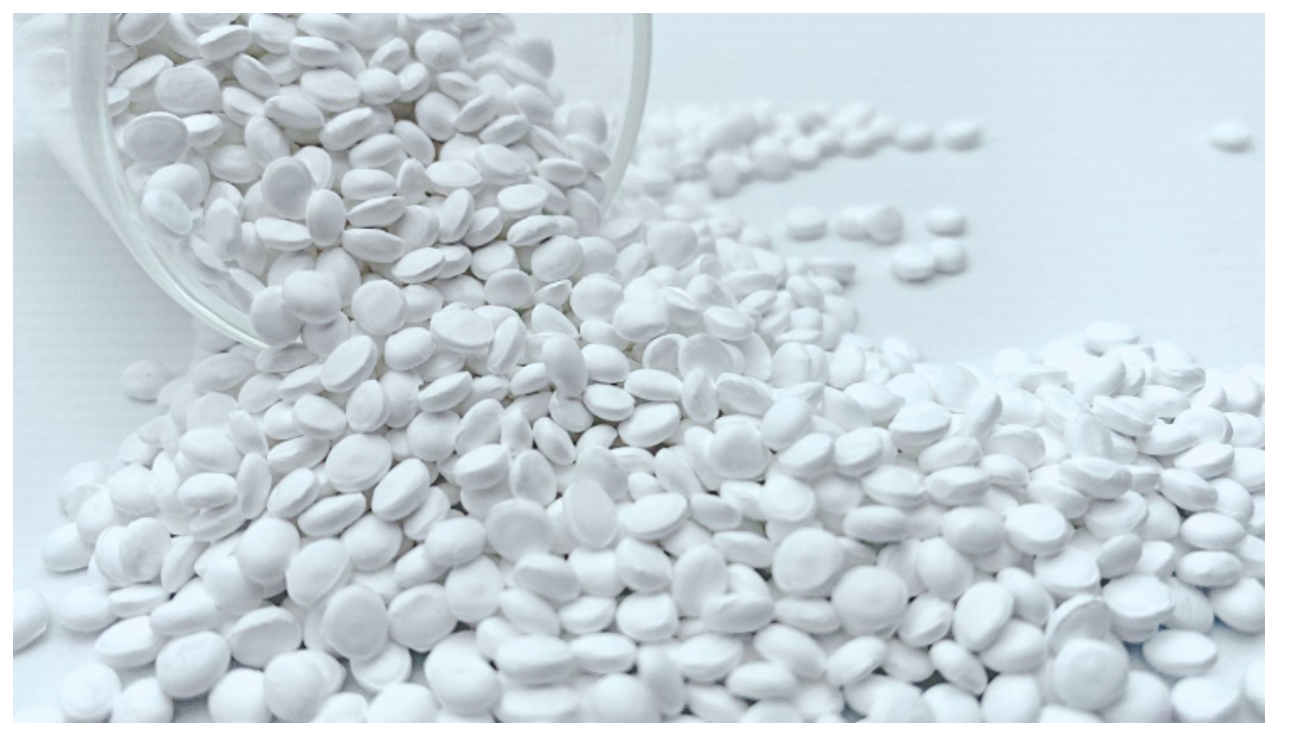

White masterbatch is a masterbatch additives which concentrated mixture of Titanium Dioxide (TiO2), carrier resin and various auxiliaries. It is used to improve the opacity, whiteness and glossiness of plastic end-products and specifically suitable for the blown film, extrusion blow, injection molding, and other products

Titanium dioxide is the most commonly produced and used white pigment in the world. It is an inorganic, crystalline, white solid that is chemically very stable. Titanium dioxide does not decompose when heated, is non-flammable and virtually insoluble in water, acids and organic solvents. These properties ensure that titanium dioxide used in products does not dissolve out of the product or degrade in any way.

With the continuous expansion of the application range of plastic products, many external plastic products, such as plastic doors and windows, building materials, and other outdoor plastic products, also have high requirements for weather resistance. In addition to rutile titanium dioxide must be used, surface treatment is required. This kind of surface treatment generally does not add zinc. Only silicon, aluminum, zirconium, etc. are added. The silicon has a hydrophilic and dehumidifying effect, which can prevent pores caused by water evaporation when plastic is extruded at high temperature.

White color masterbatches are concentrated mixtures of TiO2 pigment, additives, and a polymer carrier used to give a variety of plastic products an attractive white appearance. They are vital to the plastics industry because they supply opacity and color, both of which are necessary for different applications. TiO2, or titanium dioxide, is the main ingredient in white masterbatches because of its exceptional brightness and opacity. TiO₂ is the most widely used white pigment in masterbatches because of its better performance, while some may also contain other white pigments.

That’s why at US Masterbatch, rutile TiO2 is using in White Masterbatch manufacturing, this type offers high coverage and good UV resistance, commonly used in applications requiring high color durability and protection against sunlight

Our white plastic masterbatch not only meets but also exceeds customers’ expectations for a stable & high-quality, versatile and flexible applications to different machine or technology. With morden equipment and a team of experienced technicians in the plastic industry and Masterbatch production. We are committed to constantly innovating and improving our products to always be at the forefront of white plastic masterbatch production, accompanying the development of the global plastics industry.