Unlocking the Versatility of PE Wax: Applications Across Industries

At US Masterbatch, we understand the vital role that polyethylene (PE) wax plays in various industries. With its low melt viscosity, high melting point, and excellent chemical resistance, PE wax is an indispensable additive. Let’s explore how it enhances different applications.

1. Plastics Industry

PVC Processing

PE wax serves as an external lubricant in PVC manufacturing, reducing friction between polymer chains and processing equipment. It also:

- Improves melt flow and lowers torque during extrusion and calendering.

- Enhances surface gloss and minimizes plate-out.

- Facilitates mold release in injection molding processes.

PE Pipe Production

- Enhances processing by improving melt flow and extrusion rates.

- Reduces die drool, ensuring a smoother surface finish.

- Increases resistance to environmental stress cracking, extending pipe durability.

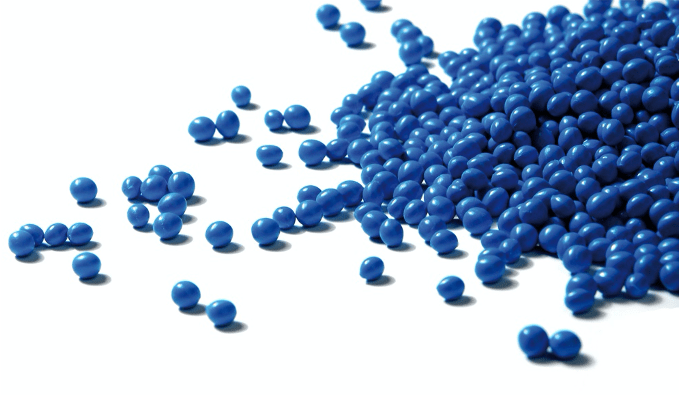

Masterbatch Manufacturing

- Acts as a dispersing agent for pigments and additives, ensuring uniform distribution.

- Reduces melt viscosity, improving the processability of highly filled masterbatches.

- Enhances the surface quality and dispersion of final plastic products.

Polyolefin Processing

- Functions as a lubricant during extrusion and injection molding.

- Improves the surface finish of polyolefin products.

- Reduces energy consumption during processing.

2. Rubber Industry

Mold Release

- Provides excellent mold release properties, preventing rubber compounds from sticking.

- Enhances the surface finish of molded rubber products.

Surface Lubrication

- Reduces friction and enhances lubricity in rubber compounds.

- Improves processing in extrusion and calendering applications.

3. Ink and Coatings

Printing Inks

- Increases scratch and rub resistance of printed surfaces.

- Enhances water repellency and gloss.

- Functions as a matting agent in certain formulations.

Coatings

- Improves scratch resistance, water repellency, and mar resistance.

- Enhances surface smoothness and gloss.

- Increases water resistance in wood coatings.

4. Adhesives

Hot Melt Adhesives

- Reduces melt viscosity, improving flow and application.

- Enhances flexibility and adhesion properties.

- Increases heat resistance in adhesive formulations.

Other Adhesives

- Acts as a modifier to improve adhesion and flexibility in various formulations.

5. Candles

Enhanced Burning Quality

- Regulates burning rate for more consistent performance.

- Enhances fragrance release.

- Increases candle hardness for improved durability.

6. Textiles

Water Repellency

- Enhances water resistance of textile fabrics.

- Improves the durability of textile finishes.

Why Choose US Masterbatch?

At US Masterbatch, we specialize in delivering high-quality PE wax solutions tailored to industry needs. Our commitment to innovation and excellence ensures that our customers benefit from top-tier products for enhanced performance and processing efficiency.

Conclusion

By leveraging the unique properties of PE wax, US Masterbatch helps manufacturers across industries enhance product quality and optimize production. Whether used in plastics, rubber, inks, adhesives, candles, or textiles, PE wax continues to be a vital component for industrial success.