What is Thermoplastic Elastomer meaning?

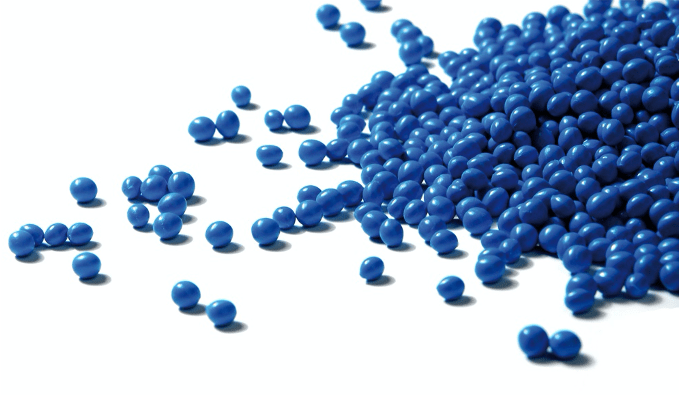

TPE (Thermoplastic elastomer) is well known for its comfort, safety and efficiency. It is nowadays an indispensable material in plastic industries. Thanks to its ability to combine the features of rubber and the processing advantages and recyclability of plastics, it becomes an ideal choice for many product research and development specialists. So, what is thermoplastic elastomer meaning, its features and applications? Let’s together with us dig into this article for the definition and usage of thermoplastic elastomers.

What is Thermoplastic Elastomer meaning?

Thermoplastic: is one type of plastic that can become soft and moldable at a heating temperature and hardens upon cooling. It is different from thermosetting plastics which become solid permanently after being heated, thermoplastic can be reheated, reshaped and reused many times.

Elastomer: is one kind of rubber – like material with elastic properties. It can return to their original shape after stretched or significantly deformed

So, what is thermoplastic elastomer meaning? It is combination of the properties of thermoplastic and elastomer with the flexibility and elasticity of rubber. Thanks to that, thermoplastic elastomer brings the versatility and values to wide range of plastic applications.

Key properties of thermoplastic elastomer.

We have come through what Thermoplastic Elastomer meaning is. Now let’s go analyze the key properties of thermoplastic to understand why it has various applications in the plastic industry.

Physical properties:

Elasticity: As we mentioned in “What is thermoplastic elastomer meaning” part, elasticity is one of the main characters of this materials. For better imagination, it can be considered as rubber – like material.

Stiffness: Thermoplastic Elastomer has various formations from very soft to gel – like or even hard.

Low density: Density of thermoplastic elastomer is normally lower than thermosetting rubber, which allows it to be used widely in applications requiring lightweight materials such as injection and blow molded products.

Mechanical properties:

Good tensile strength: Thermoplastic elastomer has the ability to withstand high pulling force without breaking.

Flexibility and impact resistance: Its high flexibility is seen clearly when it is bent. Compared to rigid plastic, it is more flexible and bendable. In the meantime, it is excellent in impact resistance also.

Abrasion resistance: Thermoplastic elastomer is resistant to wear and tear, which allows them to be heated and used repeatedly.

Thermal properties:

Thermoplastic elastomer can be processed by traditional thermoplastic methods including injection and blow molding or extrusions. Its’ melting point is from 260 to 320 degrees, allowing it to be very suitable for manufacturing injection molding and extrusion in high volumes.

Chemical properties:

Chemical resistance: The chemistry and morphology of the thermoplastic elastomer give it excellent resistant ability to chemicals, oil and solvents

Weather resistance: Thanks to its compositions, thermoplastic elastomer can withstand a wide range of temperatures and environmental factors. Some kinds of thermoplastic even can resist UV radiation, ozone and weathering.

Electrical properties:

Thermoplastic Elastomer has special electric insulation ability, which makes them very good for making cables and electronic components. The excellent level of electrical insulation allows it to withstand high electric fields without breaking down.

Eco-friendly properties:

Recyclability: Thermoplastic elastomer is both made from recycled plastics and can be processed to be recycled which is safe to the environment.

Easy processing: Thermoplastic elastomer requires very less energy in production process and easily molded and extruded. That’s why it is called eco-friendly materials in plastic industries.

Comfortability and color matching ability:

Comfortable touch: In “thermoplastic elastomer meaning” part, we understand this material is rubber – like, which provides a comfortable touch and makes it very suitable for consumer products.

Colorability: Thermoplastic elastomer can be compatible with both pigment and dyes. It is easily mixed with a full spectrum of colors, which gives a wide range of color options.

Safe for food and medical contact:

Thermoplastic elastomer is safe for people health even it contains some chemicals to increase flexibility of products. It is proved that this chemical is found in thermoplastic elastomer, but the percentage added is too small to cause any harm to people’s health. And thanks to its biocompatibility and non – toxic features, it is widely used in medical and food – contact applications.

Thermoplastic elastomer applications.

So, what thermoplastic elastomer is used for? Thanks to its various excellent properties, it has been widely used in many sectors for decades. The following are some outstanding applications of thermoplastic elastomer.

Automative industry: Thermoplastic elastomer is found in some important parts of automative productions such as seals and gaskets; Bumpers and Exterior Trim; Interior Components or Hoses and Tubing.

Consumer goods: Thanks to its safety for food contacts, it is widely used in consumer goods. You can find thermoplastic elastomer in your everyday – life products such as soft – touch grips; footwears; toys or sport equipment

Medical devices: Some equipment in the medical industry such as tubing, Syringe Plungers and Stoppers or Wearable Devices are using a lot of thermoplastic elastomer to increase the flexibility and biocompatibility of products.

Electronical equipment:

Above we have known about the excellent electric insulation of thermoplastic. And this feature also allows it to be used in electronics fields with products named Cable Insulation, Connectors and Grommets or Keypads and Buttons

In additions to above key applications of thermoplastic elastomer, it is also used in many other applications such as packaging, construction, household goods or textiles, …

In conclusion, thermoplastic elastomer plays an important role in modern manufacturing and product design thanks to its flexibility, durability and recyclability.

Common types of thermoplastic elastomer:

Thermoplastic elastomer is formed in some types such as Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), Polystyrene (PS), Acrylonitrile Butadiene Styrene (ABS), Polymethyl Methacrylate (PMMA) and Polycarbonate (PC)

Thermoplastic elastomer in Us Masterbatch

Us Masterbatch is a Vietnamese market leader in the field of manufacturing CaCO3 filler masterbatch, Color masterbatch, Additives masterbatch & PVC compounds. We own 4 factories with a capacity of 408,000 tons per year using modern technology in production and being fully equipped with testing devices to ensure product quality.

Our main product is filler masterbatch with PE and PP base (types of thermoplastic elastomer) with various applications in packaging such as PE film blowing, PP woven sack, spun bond nonwoven, injection molding and blow molding products.

In Us Masterbatch, we always follow slogan: ‘WE SAY WE DO”. The philosophy has been engraved in the mind of every employee at Us Masterbatch.