Solve Moisture Problems in Plastics with US Masterbatch’s Desiccant Masterbatch

The Challenge: Moisture in Plastic Processing

Moisture contamination is a common issue in plastic manufacturing, especially when using recycled materials. Excess moisture can cause serious defects such as:

- Surface imperfections like bubbles, streaks, and fisheyes.

- Reduced mechanical strength, leading to brittle and weak final products.

- Processing inefficiencies, including increased rejection rates and production downtime.

To combat these challenges, manufacturers rely on Desiccant Masterbatch—a highly effective solution for moisture removal.

What is Desiccant Masterbatch?

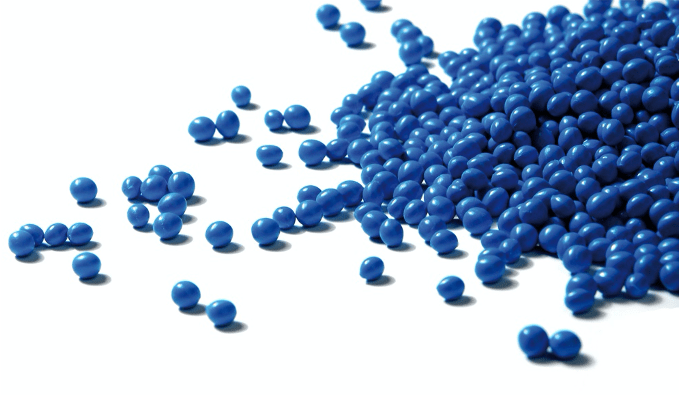

Desiccant Masterbatch is an additive used in plastic processing to absorb and neutralize moisture present in raw materials or production environments. It is composed of a carefully formulated blend of:

- Calcium oxide (CaO) – A highly effective moisture-absorbing agent.

- Carrier resins (PE, PP, etc.) – Ensuring compatibility with various plastic formulations.

- Processing aids – Enhancing dispersion and performance during production.

How Does It Work?

During processing, the Calcium oxide in Desiccant Masterbatch reacts with moisture, forming stable compounds that prevent the release of steam or gas. This eliminates the need for costly pre-drying and significantly reduces defects caused by moisture.

Why Choose Desiccant Masterbatch from US Masterbatch?

At US Masterbatch, we offer high-performance Desiccant Masterbatch designed for superior efficiency and product quality. Our solution provides:

✔ Exceptional Moisture Absorption – Effectively removes moisture from recycled plastics and raw materials.

✔ Enhanced Processing Efficiency – Eliminates hydrolysis issues in extrusion, injection molding, and blow molding.

✔ Improved Product Quality – Minimizes surface defects and ensures a flawless finish.

✔ Cost Savings – Reduces material waste and eliminates the need for pre-drying.

✔ Eco-Friendly Benefits – Enables the use of high-recycled-content plastics, promoting sustainability.

Applications

Our Desiccant Masterbatch is ideal for:

- Recycled Plastic Processing – Improving the quality of recycled PE, PP, and other resins.

- Blown Film & Injection Molding – Preventing moisture-related defects in films, sheets, and molded products.

- Pipe & Sheet Extrusion – Enhancing structural integrity and surface smoothness.

Partner with US Masterbatch

As Vietnam’s second-largest manufacturer of filler and additive masterbatches, we are committed to providing innovative solutions that elevate your plastic production. Our technical expertise ensures that you receive only the best products for optimized manufacturing processes.

Contact Us Today! Discover how our Desiccant Masterbatch can improve your production efficiency and product quality. Get in touch with our expert team for consultations and samples.

📩Email: john@usmasterbatch.com

📞 Phone: +84 915 306 960