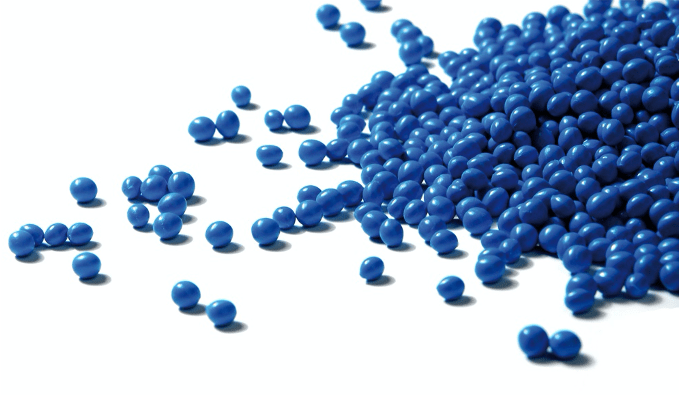

Flexible PVC Compounds: Enhancing Versatility in Modern Applications

Flexible PVC (Polyvinyl Chloride) compounds are essential in numerous industries, thanks to their outstanding versatility, durability, and cost-effectiveness. These compounds are made by adding PVC plasticizers to the base polymer, which transforms rigid PVC into a flexible, elastic material. By combining PVC with various additives, flexible vinyl or elastic PVC compounds can be customized to meet the specific requirements of different applications. This article explores the applications, properties, and processing methods of flexible PVC compounds, with a special focus on how US Masterbatch offers high-quality PVC solutions for diverse needs.

Applications of Flexible PVC Compounds

Flexible PVC compounds are used in a broad spectrum of industries, owing to their adaptable properties. Some of the key applications include:

1. Automotive Industry Flexible PVC compounds are widely used in automotive interiors, including upholstery, flooring, dashboards, and trim. Their durability, resistance to temperature changes, and easy maintenance make them ideal for automotive applications. Moreover, their UV resistance ensures that these materials retain their color and finish even after prolonged exposure to sunlight.

2. Construction and Building Materials PVC compounds are highly popular in construction for products like plumbing pipes, electrical cables, flooring tiles, and roofing membranes. The material’s durability, resistance to weathering, and ease of installation make it suitable for both indoor and outdoor applications. Flexible PVC compounds can withstand moisture, chemicals, and harsh weather conditions, ensuring longevity and reliability in construction projects.

3. Medical and Healthcare In healthcare, flexible PVC compounds are essential for making medical tubing, blood bags, IV bags, and catheters. These materials need to be flexible, sterilizable, and resistant to chemicals, which is where PVC compounds excel. PVC plasticizers in these compounds ensure that the material remains soft and flexible, making it comfortable for patients and safe for medical use.

4. Consumer Goods Flexible PVC is used in the production of various consumer goods such as footwear, clothing, and toys. The flexibility and durability of PVC allow manufacturers to create products that are comfortable, long-lasting, and resistant to wear. Faux leather items, waterproof clothing, and soft plastic toys are just a few examples of flexible PVC’s versatility in consumer goods.

5. Packaging Flexible PVC compounds are often used for packaging products like shrink wraps, cling films, and flexible packaging solutions. PVC’s ability to stretch and conform to different shapes without breaking makes it perfect for packaging applications that require flexibility and durability. Moreover, PVC films can be customized with specific barrier properties to protect the contents from moisture, light, and oxygen.

6. Flexible Hoses, Gaskets, and Seals Flexible PVC compounds are widely used in the production of hoses, gaskets, and seals, especially in industries such as automotive, agriculture, and construction. Their elasticity and chemical resistance make them ideal for environments where the material must endure various temperatures and exposures without losing shape or functionality.

7. Footwear In the footwear industry, flexible PVC compounds are used to manufacture sandals, boots, and other shoes. The material’s ability to provide both comfort and durability is critical, and its resistance to wear ensures that PVC footwear remains functional for long periods.

Properties of Flexible PVC Compounds

Flexible PVC compounds are known for a combination of desirable properties that make them suitable for a variety of applications:

1. Elasticity and Flexibility The primary advantage of flexible PVC is its elasticity. PVC plasticizers are added to the base polymer to reduce rigidity, allowing the material to bend, stretch, and flex without cracking. This makes flexible PVC ideal for applications that require high levels of flexibility.

2. Durability and Longevity Flexible PVC compounds are known for their robustness and long-lasting performance. They offer excellent resistance to weathering, UV degradation, and chemical exposure. These properties make them perfect for use in products that must withstand harsh environments or extended use, such as plumbing pipes, automotive components, and medical devices.

3. Chemical Resistance Flexible PVC compounds are highly resistant to a wide range of chemicals, including acids, alkalis, and solvents. This makes them an excellent choice for industries where exposure to aggressive chemicals is common, such as the automotive and medical sectors.

4. Electrical Insulation Flexible PVC is an excellent insulator, making it an ideal material for electrical cables and wiring. Its flexibility combined with electrical resistance ensures the safety and functionality of electrical products.

5. Cost-Effective Flexible PVC is lightweight and relatively inexpensive, making it an attractive option for manufacturers looking to balance performance and cost. This cost-effectiveness extends across a range of industries, from consumer goods to medical devices, without compromising the material’s quality.

6. Recyclability PVC is a recyclable material, which makes flexible PVC compounds an environmentally friendly choice for many applications. After the end of their useful life, PVC products can often be melted down and reused in the production of new items, helping reduce the environmental impact of PVC waste.

Processing of Flexible PVC Compounds

The processing of flexible PVC compounds involves various techniques designed to optimize the material’s properties for specific applications. Some of the most common methods include:

1. Extrusion Extrusion is the most widely used method for processing flexible PVC. In this process, the compound is melted and forced through a die to form continuous shapes, such as pipes, profiles, and sheets. Extrusion is ideal for producing large volumes of flexible PVC components, including plumbing systems and automotive parts.

2. Injection Molding Injection molding is another method used for producing flexible PVC products. The material is injected into a mold under high pressure, allowing for the creation of detailed and complex shapes. This method is particularly useful for producing high-precision parts, including medical devices and electrical components.

3. Calendering In the calendering process, flexible PVC is passed through a series of rollers to form thin sheets or films. This method is often used in applications like flooring, wallpapers, and packaging. The ability to control thickness and texture makes calendering ideal for producing a wide range of PVC products.

4. Blow Molding Blow molding is a process used to create hollow flexible PVC products, such as

bottles and containers. The PVC compound is heated and inflated inside a mold, taking on the shape of the mold while maintaining flexibility and strength.

5. Compounding and Additives PVC plasticizers, stabilizers, flame retardants, and fillers are mixed into the base PVC resin to create the desired properties. These additives improve performance in various ways, such as increasing flexibility, enhancing chemical resistance, or providing fire resistance.

Choose US Masterbatch’s PVC Compounds for Superior Quality!

US Masterbatch offers a comprehensive range of high-quality PVC compounds that meet the specific needs of industries such as automotive, medical, construction, flexible hoses, gaskets, seals, and footwear. Our compounds are formulated with the best PVC plasticizers and additives to deliver superior flexibility, durability, and performance.

For more information or to inquire about our PVC compounds, please contact us at:

· PIC: Ms. Zoey

· Phone: +843 48 280 698

· Email: zoey@usmasterbatch.com

Let US Masterbatch be your trusted partner in providing high-performance PVC solutions tailored to your business needs.