What Is PVC Compound? Classification and Practical Applications in Manufacturing

1. What is PVC Compound?

PVC compound is a pre-mixed formulation of PVC resin blended with additives such as plasticizers, heat stabilizers, lubricants, and color pigments. Instead of purchasing raw materials and mixing them manually, manufacturers can directly use PVC compound for extrusion or injection molding.

In other words, it is a ready-to-use PVC material, ensuring stable quality and saving production time.

👉 Easy example:

If pure PVC resin is like raw flour, then PVC compound is the dough already mixed with sugar, eggs, and butter — you just “bake” it to get the final product.

This approach ensures consistent color, flexibility, and mechanical strength across every batch.

2. Classification

Based on physical properties and applications, PVC compounds are generally divided into two main groups:

| Type | Characteristics | Common Applications |

| Flexible | Soft, elastic, contains plasticizers | Hoses, wires & cables, gaskets, footwear |

| Rigid | Hard, impact-resistant, no plasticizer | Pipes, fittings, window profiles |

This clear classification helps manufacturers choose the right compound for their processing technology — such as extrusion, injection molding, or calendering.

3. Applications of Flexible Type

Flexible PVC compound offers excellent elasticity and high flexibility, making it one of the most commonly used materials in daily life and industrial products.

Below are the four most popular application groups:

3.1 Hose Applications

Flexible PVC compound can be adjusted from very soft to semi-rigid, suitable for producing garden hoses, suction hoses, air hoses, or industrial tubes.

Features:

- Easy to bend without cracking

- Transparent or colored as desired

- Suitable for low to medium pressure

👉 Example:

The flexible plastic hose connected to your water pump or garden sprayer is made from PVC hose compound — soft yet strong enough not to deform under water pressure.

3.2 Wire & Cable

PVC compound is widely used for insulation and outer sheathing of wires and cables thanks to its excellent electrical insulation, weather resistance, and flame retardancy.

Features:

- Safe electrical insulation, light oil resistance

- Easy to extrude and process

- Good heat and impact resistance

Applications: household wires, data cables, phone chargers, industrial cables.

👉 Example:

The outer layer of the power cable in your home or your phone charger is made from PVC wire & cable compound — protecting the copper core from moisture while ensuring electrical safety.

3.3 Gasket / Sealing Applications

PVC compound can be formulated to achieve high elasticity and tight sealing, making it ideal for gaskets, edge trims, and sealing profiles.

Features:

- Soft, airtight, and waterproof

- Resistant to low temperatures and shrinkage

- Can be extruded into complex cross-sections

Applications: refrigerator gaskets, window seals, container door seals, car door seals.

👉 Example:

The soft rubber-like seal around your refrigerator door that keeps cold air inside is actually made from PVC gasket compound, ensuring airtight sealing and energy efficiency.

3.4 Footwear Applications

In the footwear industry, PVC compound is favored for its ease of molding, wide color range, and comfortable softness.

Features:

- Flexible, soft, and waterproof

- Adjustable hardness for soles or straps

- Suitable for molding, extrusion, or injection processes

Applications: shoe soles, straps, rain boots, safety shoes, children’s shoes.

👉 Example:

The colorful sandals or rain boots you see in markets are made from PVC shoe compound — durable, lightweight, and easy to clean.

4. Applications of Rigid Type

Rigid PVC compound contains no plasticizers, resulting in high rigidity and excellent impact strength.

It is used in products that require structural stability and weather durability.

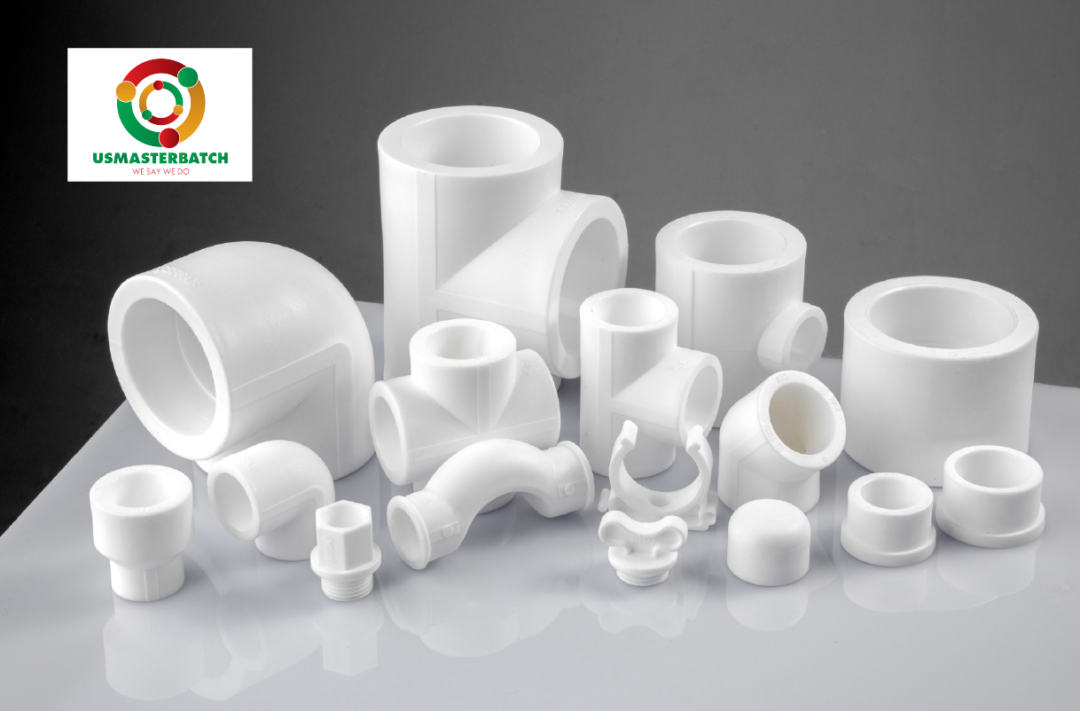

4.1 Pipe & Fitting

This is the most common application of rigid PVC compound.

Thanks to its pressure resistance, corrosion resistance, and long service life, it is used in most water supply and drainage systems.

Features:

- Hard, durable, and chemical-resistant

- Rust-free compared to metals

- Easy to weld, join, and process

Applications: water pipes, chemical pipes, rainwater drains, and pipe fittings (elbows, tees, flanges, valves).

👉 Example:

The white PVC pipe system in your home is made from rigid PVC pipe compound, designed to last over 20 years under normal conditions.

4.2 Profiles (Extruded Sections)

PVC profile compound is designed for long, fixed cross-section products such as door and window frames, trims, or decorative panels.

Features:

- High rigidity and dimensional stability

- UV-resistant, color-retaining under sunlight

- Smooth surface and easy extrusion

Applications: uPVC window profiles, plastic frames, sliding tracks, wall trims, decorative panels.

👉 Example:

The white plastic window frames in modern buildings are made from rigid PVC profile compound, offering sound insulation, heat resistance, and rust-free performance compared to aluminum or steel.

5. Advantages

Using pre-formulated PVC compound instead of mixing raw materials offers significant advantages for manufacturers:

- Saves production time: no need for manual additive blending.

- Ensures consistent quality: each batch follows a controlled formula.

- Easy customization: adjust hardness, color, transparency, flame retardancy, or heat resistance as needed.

- Reduces technical risks: fewer issues with burning, air bubbles, or color variation during processing.

👉 Example:

If you produce both flexible hoses and electric cables, you can use two different types— one optimized for softness, another for insulation — ensuring consistent product quality without changing machine settings frequently.

6. Conclusion

PVC compound is an optimized solution that helps manufacturers improve productivity, maintain quality consistency, and reduce production costs.

From flexible applications such as hoses, cables, gaskets, and footwear to rigid applications like pipes and profiles, it remains one of the most versatile and efficient materials in modern manufacturing.

👉 If you are looking for a trusted supplier in Vietnam, US Masterbatch provide:

- A wide range of compounds for each application: hose, wire, gasket, shoe, pipe, profile.

- Technical support to customize formulas as required.

- Fast sampling, stable delivery, and competitive pricing.

Contact us today to get expert consultation and find the most suitable types for your products.