The PVC Compound’s Applications In Wire and Cable Industry

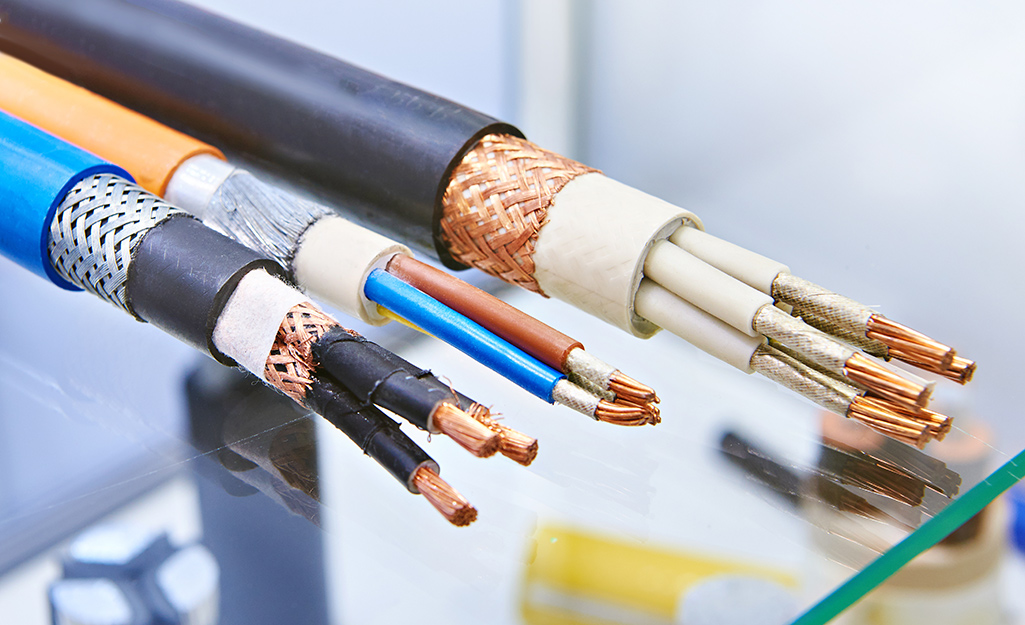

The wire and cable industry plays a crucial role in various sectors, ranging from power transmission and telecommunications to automotive and construction. In this industry, the choice of materials is of paramount importance to ensure safety, durability, and performance. One such versatile material is PVC compound, which has become widely prevalent due to its exceptional properties and numerous applications.

Polyvinyl chloride (PVC) compound, a versatile thermoplastic material, has revolutionized the wire and cable industry. Its exceptional electrical, mechanical, and thermal properties make it an ideal choice for various applications. This article explores the diverse applications of PVC compound in the wire and cable industry, highlighting its benefits and significance in modern electrical systems.

- Insulation and Jacketing:

PVC compound is widely used as insulation and jacketing material for electrical wires and cables. Its excellent electrical insulation properties ensure safe and reliable transmission of power. PVC’s high dielectric strength and low dielectric constant contribute to the efficient insulation of conductors, preventing leakage of electricity and reducing the risk of short circuits.

Furthermore, PVC’s resistance to chemicals, oils, and moisture makes it advantageous for cable jacketing applications. It provides a protective barrier against environmental factors, enhancing the longevity and durability of cables.

- Flame Retardancy:

One of the major causes of fire and explosion is the lack of safety when using electrical equipment, overloading the line, flammable materials. Fire safety is a critical concern in the wire and cable industry. PVC compounds are available in flame-retardant formulations that inhibit the spread of fire. These compounds are designed to self-extinguish when the ignition source is removed, minimizing the risk of fire propagation. The incorporation of flame-retardant additives in producing PVC compound help to make fire fighting better, thereby reducing the cause of fire.

- Low Smoke and Halogen-Free:

For plastic materials, when used for a long time or burned, it will react and produce some harmful gases. These factors will affect human health and the environment in the long term. In recent years, there has been a growing demand for low smoke and halogen-free cables, especially in applications where fire safety is a critical concern. PVC compounds can be formulated to meet these requirements by incorporating flame retardant additives and minimizing the release of toxic gases during combustion. This makes PVC compounds more safe and be an excellent choice for wiring in buildings, transportation systems, and others applications.

Currently, the US Masterbatch factories are manufacturing and researching all the necessary properties and ensuring the requirements of partners in the field of cable production. All output products are strictly tested for quality, highly appreciated by customers as well as meeting international standards.

If you have any questions or inquiries, please do not hesitate to contact us via:

Email: neil@usmasterbatch.com ; helen@usmasterbatch.com

Phone: +84 984 778 391 ; +84 949 786 336