9 Common Defects in using PVC Compound for Pipe Fittings Production

9 Common Defects and Detailed Solutions in PVC Compound Production for Pipe Fittings

1. Defect: Brittleness / Cracking

Causes:

- Incomplete Fusion/Gelation.

- Insufficient amount of Impact Modifier or Plasticizer.

- Processing temperature is too low (insufficient energy for fusion).

- Using PVC resin with a very low K-value.

Solutions:

- Enhance the use of Processing Aid (ACR) and Impact Modifier (CPE/ABS).

- Increase the barrel temperature profile and/or holding pressure in injection molding.

- Control the high-speed mixing temperature to reach the optimal Fusion Temperature range of 110°C – 125°C to ensure complete homogenization.

- Use K-67 to K-71 resin for pressure fittings.

2. Defect: Poor Surface Finish (Rough, Pitting, Matte)

Causes:

- Poor dispersion of raw materials (powder/additives) during mixing.

- Residual moisture in the compound or filler.

- Imbalance between Internal Lube and External Lube.

- Overheating during extrusion/molding causing additive volatilization or slight degradation.

Solutions:

- Increase the time and speed of high-speed mixing to achieve uniform dispersion.

- Dry the compound/raw materials before processing.

- Balance the Lube system: Slightly increase External Lube (PE Wax, Paraffin) for gloss, but avoid excess to prevent plate-out.

- Lower the temperature of the metering zone and die head if signs of burning/volatilization are observed.

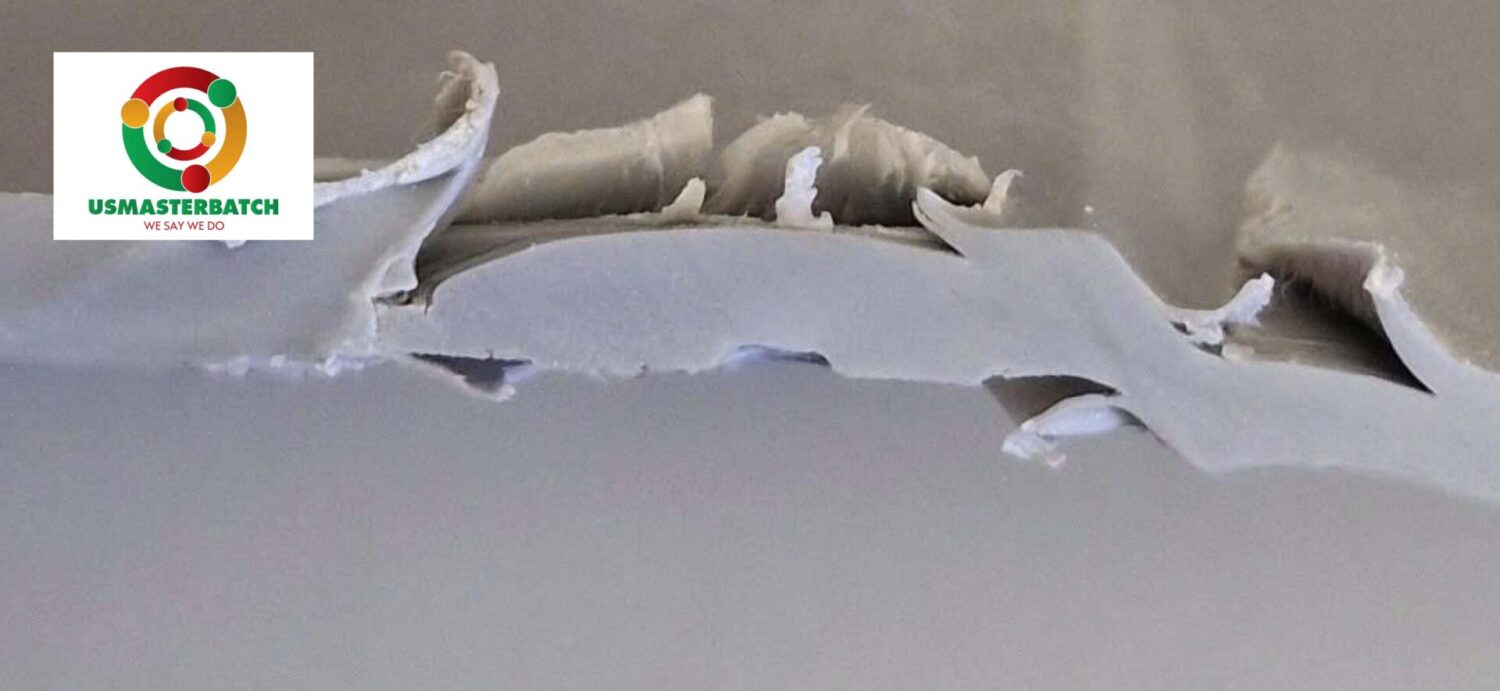

3. Defect: Poor Fusion / Delamination

Causes:

- Low degree of fusion (incomplete gelation).

- Extrusion/injection speed is too fast, giving insufficient heating time.

- Screw design does not generate enough shear stress.

Solutions:

- Increase ACR in the formulation to promote the fusion process.

- Adjust the screw speed (slightly decrease) to increase the residence time and degree of fusion.

- Slightly increase the processing temperature or increase the Back Pressure in injection molding to boost shear friction.

- Check the heat stabilizer system and supplement if necessary to maintain material stability throughout the fusion process.

4. Defect: Low Impact Strength, Low Elongation

Causes:

- Insufficient amount of Impact Modifier such as CPE, ACR.

- Poor homogeneity of the compound.

- Unstable quality of the input PVC resin.

Solutions:

- Add an appropriate amount of CPE or ACR to the formula to increase toughness.

- Control the mixing process to ensure uniform dispersion of the Modifier in the compound.

- Use resin from reliable suppliers with the appropriate K-value (typically K-67).

5. Defect: Yellowing / Discoloration

Causes:

- Thermal Degradation due to excessively high temperatures in certain zones.

- Insufficient heat stabilizer to protect PVC during processing.

- High friction due to lack of Internal Lube or excessive screw speed.

- Excessive material residence time in the machine.

Solutions:

- Increase the amount of heat stabilizer (Ca-Zn) or combine with Tin Stabilizer (if necessary).

- Reduce localized temperature (especially in the die head and nozzle area).

- Increase Internal Lube to reduce frictional heat generation.

- Shorten the material residence time by optimizing the cycle or speed.

6. Defect: Bubbles / Voids

Causes:

- High moisture content in the compound or filler.

- Decomposition due to heat, generating gas.

- Excessive plasticization, causing some additives to volatilize easily.

Solutions:

- Mandatory drying of raw materials before extrusion/injection molding.

- Control the heat profile and reduce the temperature if degradation is detected.

- Check and replace easily volatile additives with those that have a higher volatilization temperature.

7. Defect: Failure to Meet Standard Pressure (PN10, PN16, …)

Causes:

- Use of unsuitable K-value resin for pressure fittings.

- Low tensile and impact strength due to insufficient Modifier.

- Inhomogeneous product due to poor fusion.

Solutions:

- Select K-67/68 resin for pressure fittings.

- Optimize the amount of ACR & CPE to improve mechanical strength.

- Check the Fusion Level and optimize screw speed and temperature to achieve high homogeneity.

8. Defect: Color Inconsistency

Causes:

- Masterbatch (Color Concentrate) poorly dispersed.

- Unstable temperature during extrusion/injection molding.

- Masterbatch quality is incompatible with the base compound.

Solutions:

- Use high-quality and compatible PVC-based Masterbatch.

- Increase mixing time and speed to ensure color dispersion.

- Maintain stable temperature during processing to prevent color changes due to heat.

9. Defect: Sink Marks / Excessive Shrinkage

Causes:

- Mold temperature is too high or cooling time is too short.

- Holding Pressure is insufficient to compensate for material shrinkage.

- Product wall thickness is too thick or non-uniform.

Solutions:

- Reduce the mold temperature for faster and more effective cooling.

- Increase the Holding Pressure and Holding Time (Packing Time) to compact the material and compensate for shrinkage.

- Increase the Cooling Time.

- Optimize the gate location and size for easy material filling and compression.